“Teamwork”

Often a simple fix becomes more involved when you live abroad. Maintenance specialist Grant Sahl tells how our team in Cameroon recently completed the job with a bit of extra effort.

This past month has been a busy one in the hangar. The numerous projects and aircraft inspections take a whole team. The director of maintenance is the most experienced with our Soloy 207’s Rolls Royce engine. However, his schedule only allows him to devote partial days to the hangar floor, so he has taken the role of overseer and passed much of the work on to others. It’s interesting and exciting for me to get to work on a new type of engine.

Recently we performed the Soloy’s 300-hour inspection and uncovered some issues. One was stripped threads on a simple plug that goes in the scroll right after the compressor. A fellow mechanic added the plug to the growing list of parts he was requesting from JAARS in the States. With the worldwide COVID-19 crisis, all parts now have to be hand-carried into the country rather than shipped. Our amazing crew at JAARS coordinated its arrival in only two weeks’ time.

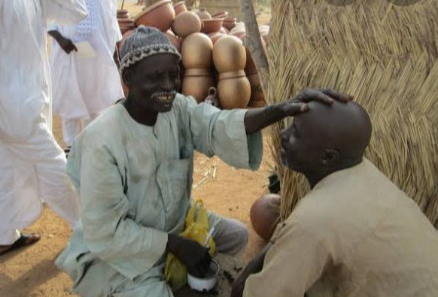

Sadly, when we began to install the new plug, we realized that the threads on the scroll were also messed up! Here in Cameroon we can’t run out to a large hardware store or order stuff for next-day delivery. We needed a tap much larger than the one we had on-hand in order to fix the threads. We had a much smaller tap with the same thread pitch on hand, so we made a bushing for it to go in.

The bushing offset the tap to allow one of the four cutting edges to extend past the bushing.

Once the assembly was installed, it chased (cleaned) the threads in the scroll. Afterwards, the plug was reinstalled, and it was as good as new! In the U.S. this would have taken only a few minutes to repair. Here it took three hours to build the bushing, repair the scroll, and many people to get the plug! I’m blessed to be a part of a great team!