Cheaper by the Dozen

THE PROBLEM

YAJASI, our aviation partner in Papua, Indonesia, had a problem. Rock guards installed on the main mounts of their Pilatus Porter aircraft were constantly cracking. These protectors were designed to prevent damage to the underside of the horizontal stabilizer (the wing-like structure on the tail) caused by rocks and debris kicked up by the wheels during operation out of gravel runways. Replacing these guards was expensive and time-consuming. Could JAARS help?

THE REASON FOR THE PROBLEM

YAJASI mechanics and JAARS machinists determined that the rock guards were breaking because of vibration from operating on rough airstrip surfaces and the occasional stress caused by passengers inadvertently using them as a step.

HOW TO SOLVE THE PROBLEM

The JAARS machine shop is all about solving engineering problems and finding ways to save precious dollars. There was an improved rock guard on the market, but it was expensive. Project manager Kyle Merkey and the machinists at Waxhaw felt they could provide YAJASI with replacement rock guards that would be as effective as the open-market design but less expensive. YAJASI initially wanted 4 sets of the rock guards, but Kyle’s team calculated that they could provide 12 sets for about the same cost as one bought on the market. “Cheaper by the dozen” was how they described it.

CHALLENGES OF THE NEW DESIGN

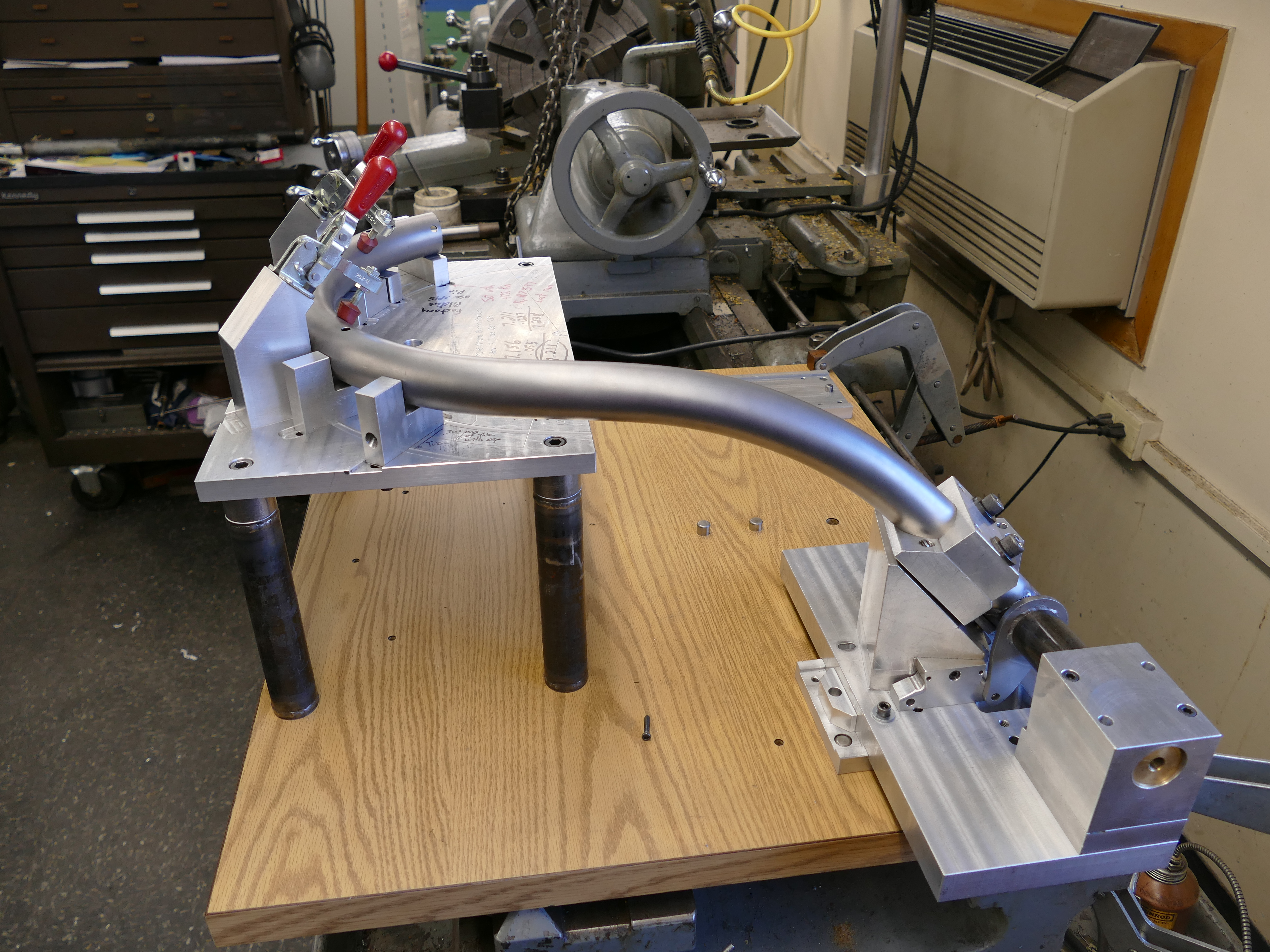

“The challenge we faced was fabricating and bending the tube assemblies exactly to specifications since there was minimal clearance between the guards and the tires,” explains Kyle. “Our machine shop came up with a procedure that would ensure the tube could be bent to specific dimensions. Machinist Jim Mohney then fabricated a special jig that would hold the bent tubes tightly in place for welding onto their attaching ears” (where the rock guards attach to the landing gear).

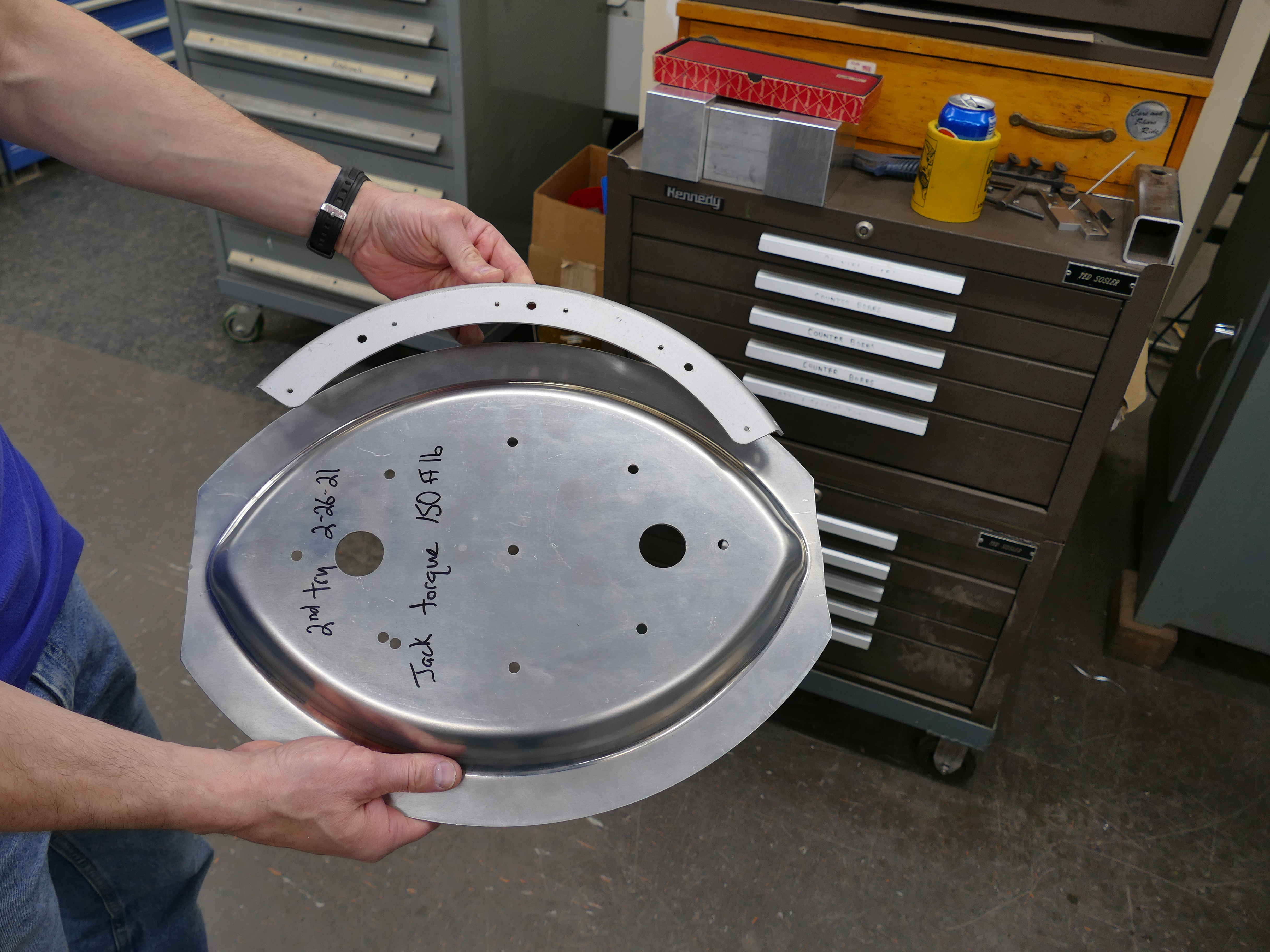

One final challenge was to fabricate a curved plate that would secure the rubber flap to the tubing. The process started with a flat sheet of aluminum.

THE RESULT

The new design attacks the damage problem in several ways:

- The new rock guard has a larger diameter main tube that is 32% stronger.

- The overall length of the main tube is 20% shorter than the old style, increasing its rigidity.

- The new design modifies the connection of the main tube to the mount tube, eliminating a welded doubler that concentrated stress to the connection.

- The new design also removes any possibility that the rock guards can be used as a step.

These improvements will save YAJASI money by reducing replacement frequency and upfront costs. The 12 JAARS–designed rock guards will cost YAJASI about the same as a single pair bought on the open market. YAJASI will now have spares for a part that should need fewer replacements.

THOSE WHO MADE IT HAPPEN

“We’re about solutions at the machine shop,” says Kyle who has used his tool-and-die maker background at JAARS for 20 years. “When I started at JAARS we mostly did fabrication of Helio parts, but as that aircraft has phased out, we have evolved into providing solutions for engineering problems, certainly in aviation but also for other transportation modes.”

Ingenuity, innovation, and hard work to solve challenging engineering problems is what the JAARS machine shop is all about. Like many departments at the Waxhaw campus, it works behind the scenes to support mission work worldwide.

To keep the machine shop providing vital support to our mission partners worldwide, please donate to JAARS CORE Mission Operations here.