The Versatile Mechanic

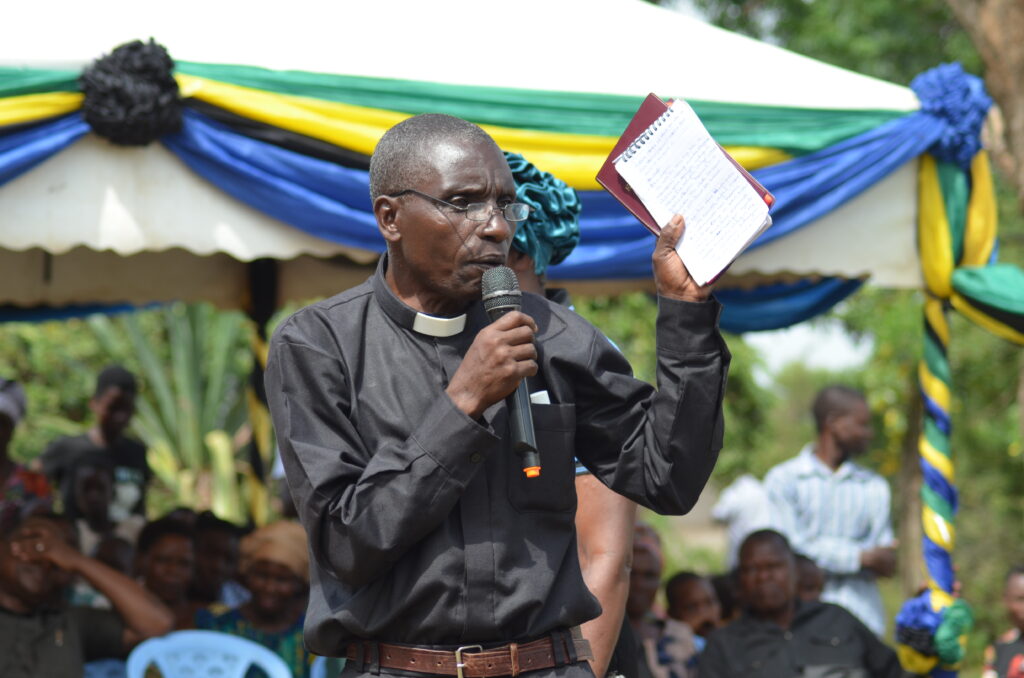

While preparing for missions, we have seen plenty of missionary brochures with pictures similar to this one we took. So, when I landed on this tiny mountain airstrip crowded with villagers, I thought, “I have made it to the brochure.”

That particular feeling of accomplishment met us often during our internship with YAJASI in Sentani, Indonesia. That seven-week period proved to be the perfect amount of time for us to get a feeling for what life might look like for us someday.

Although the airplane manuals, inspection paperwork, and aircraft components were similar to what I had been instructed on at Moody, there were plenty of new challenges in Sentani. No power in the hanger? No part in the stockroom? No Internet connection? An aviation mechanic at YAJASI would say, “No worries.” The maintenance team at YAJASI taught me how to adapt when things didn’t work as they should. When the power goes out and the generator overheats, they troubleshoot the generator or find another project to do while waiting for power to come back on. If a part is not in the stock room, they walk over to another operator’s hanger to see if they have the needed part. When an Indonesian inspector announces an inspection visit, current tasks stop to make sure the paperwork is in order for the inspection. I can definitely tell that I will have to continue to work on patience and flexibility as challenges like these change the plans for the day.

The maintenance team allowed me to really get my hands dirty! I helped with some routine maintenance on the PC-6, built a tool for measuring propeller angles, and prepared a solar-powered system for installation. Plus, I even took on a big project: a wing-removal hoist for a Pilatus PC-12.

From what I have heard, it is not common to have an intern tasked with a major project like this. I began by getting the dimensions from a picture of a similar design hoist. After scaling out the whole thing on paper, I came up with a method of disassembling the fifteen-foot-tall steel colossus for easier storage. Once these layouts had been reviewed by the lead mechanic, I set to work making the drawing come to life.

It was a great project—challenging my sheet metal layout and welding skills. I am so thankful that God blessed me with such an amazing group of guys to work with at YAJASI.

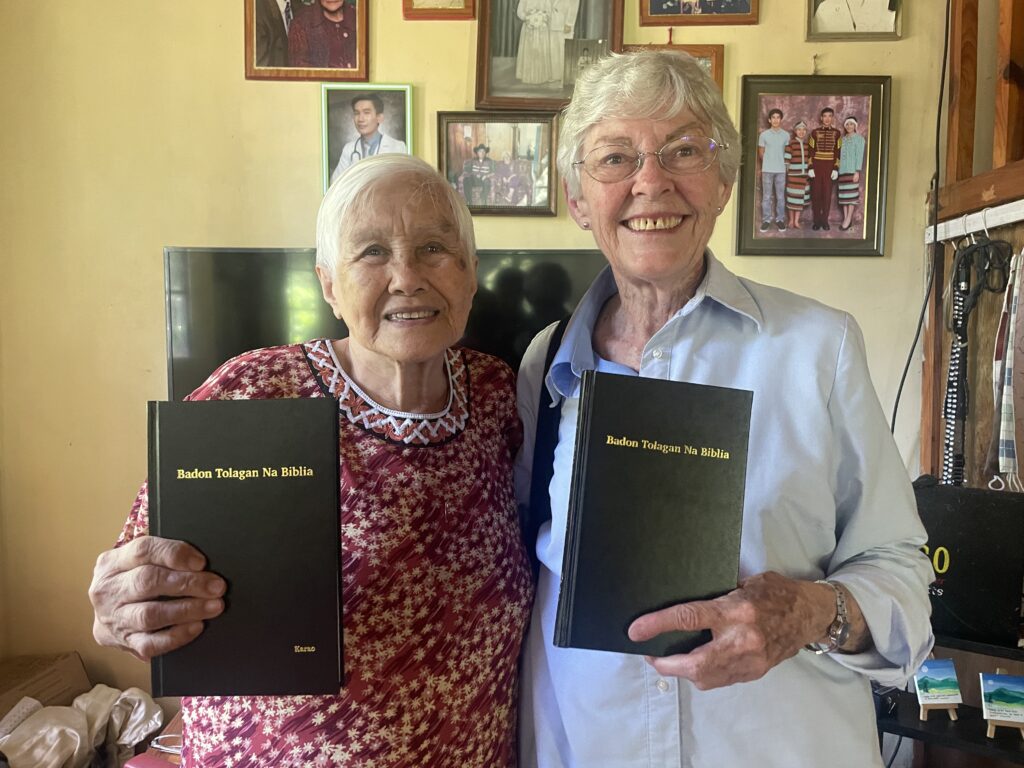

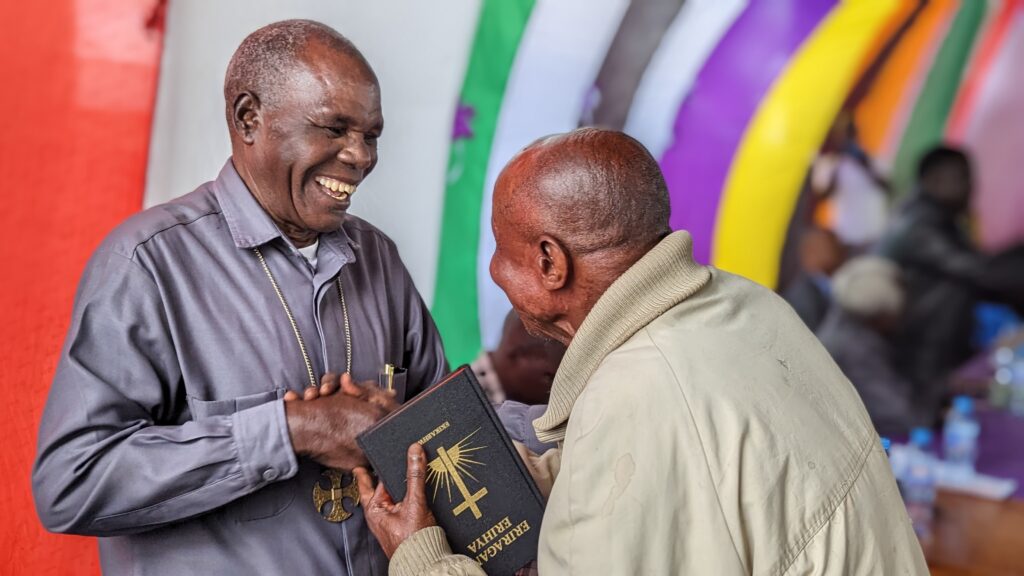

One of our favorite parts of the trip was our interaction with Indonesians. While I enjoyed working with nationals at the hangar, my wife, Karys, taught English to Indonesians at a local Indonesian school and for the national training program at the hangar, plus she tutored a group of high school students. She also learned how to cook from scratch, buy groceries in a foreign country, and work with the quirks of taking care of our home.

Our trip reignited our excitement about going to the mission field. We are not sure if God will take us back to Indonesia but the things we learned during the internship are helping us to prepare for the future. Spiritually, we learned a lot about thankfulness, contentment, patience, prayer, and flexibility which we want to continue to practice. We also came away with some practical things we could do. I might pursue working more with turbine engines. Karys wants to learn more about cooking meals from scratch.

The biggest difficulties we encountered were not knowing the language well and depending on others for transportation. These struggles only gave us more motivation to invest ourselves fully in language school in a couple years and to buy a manual transmission vehicle this semester so that we can drive ourselves in the future.

We know there will be challenges, because we have faced some of them, but we feel prepared to take them on because we have seen God’s faithfulness. Through this experience, we have confidence that God will continue to prove faithful just as he was during our trip to Indonesia.